The rubber and plastics sector is the key element of modern-day manufacturing. Canadian Feed Screws plays a significant role in empowering the plastics manufacturing sector. Our barrels and feed screws are essential to production procedures, such as blow molding, extrusion, and injection molding.

Injection Molding Screws and Barrels

In order to make intricate shapes, molten plastic material is injected into a mold. Our feed screws help to precisely measure out the material, reducing waste and guaranteeing constant product quality. From straightforward things like toys and packaging to intricate parts for the automotive and medical industries, this method is employed to create a vast array of goods.

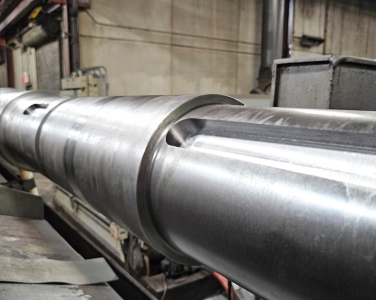

Extruder Screws and Barrels

To produce continuous shapes, plastic material gets melted and pushed through a die. Our barrels and screws maximize the extrusion process, guaranteeing accurate product dimensions and effective material flow. Numerous goods are made using this procedure, such as fibers for non-woven bags and other textile goods, films for plastic packaging and insulation, and tubes and pipes for irrigation, plumbing, and manufacturing.

Blow Molding Screws and Barrels

In order to manufacture hollow items, molten plastic is inflated into a mold. Our parts help to create complex shapes and precisely control the flow of materials. Automobile parts, bottles, and containers are just a few of the many items whose manufacturing can be made more precise using the components we create.

By offering parts that are dependable, high-quality, and adaptable, Canadian Feed Screws promotes the innovation and growth of the rubber and plastics sector.

Canadian Feed Screws is a company with dedicated employees, decades of experience, innovative machinery, and expansive facility. All these factors enable us to offer optimal engineering and manufacturing solutions, ensuring quality control every step of the way. Our devotion to customer needs sets our products above the competition and gives you components that will withstand heavy duty manufacturing processes and extreme production environments.