Facility & Capability

Advanced Manufacturing Facilities

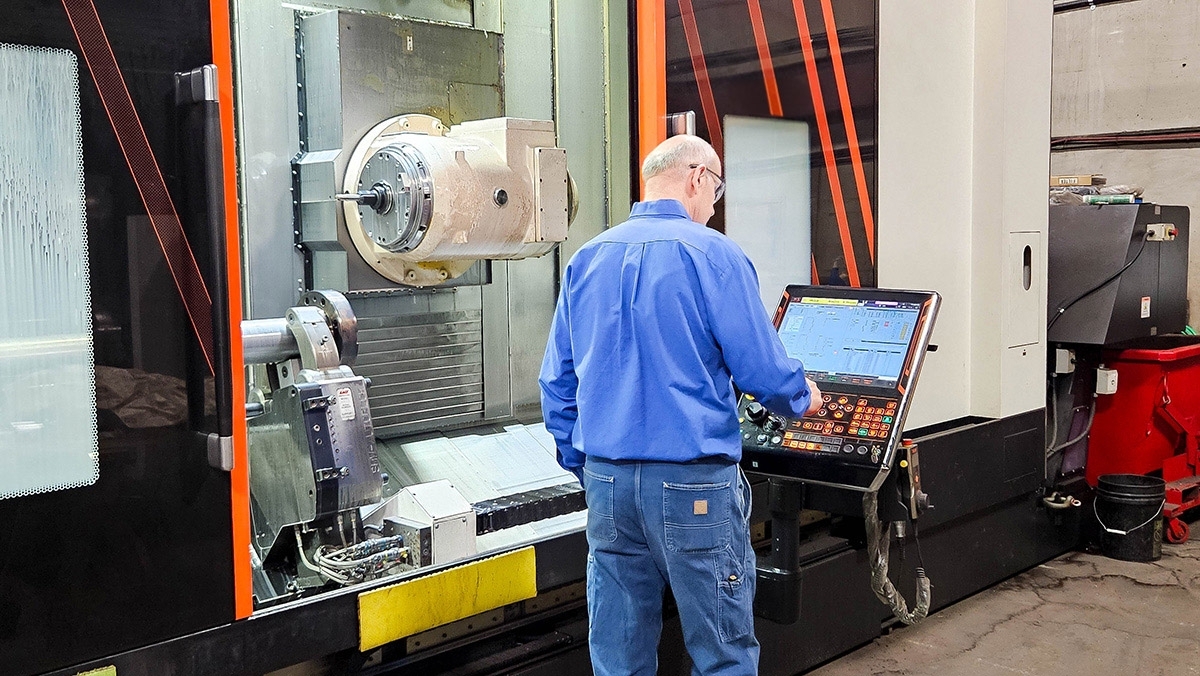

Our 30,000 sq. foot manufacturing facility features state-of-the-art equipment that enables us to create all our products in-house, from start to finish. We utilize both CNC and traditional methods to achieve the highest quality of our components. Our machines include:

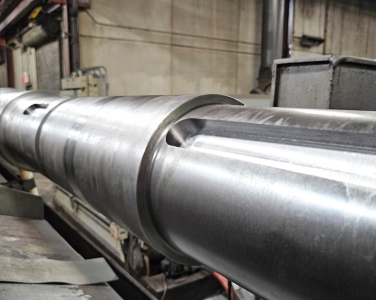

- Feed screw cutting equipment over 12m (39ft) long and 62cm (22in) in diameter

- CNC milling and turning machines

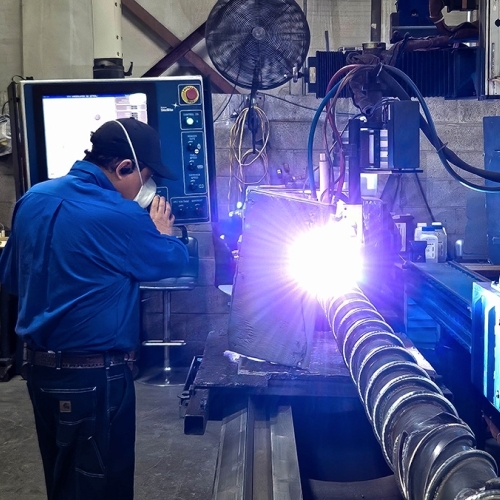

- Latest welding equipment

- Heat treatment furnaces for ion-nitriding and thru hardening

- Chrome plating equipment with max length of 8.5m (28ft)

- Deep hole boring/trepanning machines

- Honing/EDM machining

- 200 and 500 ton presses

This machinery ensures that we can handle complex projects and manufacture some of the largest screws in the world.

We utilize equipment specifically designed for complex feed screws manufacturing. A combination of forty screw cutting lathes and milling machines, plus seven welding systems allow flexibility and high volume of production. This is just one of the reasons we deliver fast without jeopardizing quality.

Canadian Feed Screws has over 45 special-purpose machine tools that allow for complex component manufacturing and customization. Moreover, our feed screw machines are capable of handling components that are up to 60ft (18m) long, giving us the capacity to produce some of the largest screws in the world.

We operate some of the largest computerized ion-nitriding furnaces in North America. Ion-nitriding is an environmentally friendly process. Nitrided parts maintain a smooth, non-porous, clean surface without distortion. We not only nitride screws and barrels, but also molds, tie bars, rotors, etc.

Canadian Feed Screws is a company with dedicated employees, decades of experience, innovative machinery, and expansive facility. All these factors enable us to offer optimal engineering and manufacturing solutions, ensuring quality control every step of the way. Our devotion to customer needs sets our products above the competition and gives you components that will withstand heavy duty manufacturing processes and extreme production environments.