The greatest standards of accuracy, precision, dependability, and cleanliness are required by the medical sector. Canadian Feed Screws provides essential parts that satisfy exact specifications and high industry standards. Numerous medical equipment and devices are produced using our barrels, feed screws, and other components.

Injection Molding Screws and Barrels

Feed screws and barrels are part of the sophisticated equipment used to manufacture high precision items through injection molding. These items include:

- Surgical instruments like forceps, scalpels, and more.

- Medical devices like drug delivery systems, IV connectors, and syringes.

Diagnostic equipment like parts for imaging equipment, blood analyzers, and other diagnostic devices.

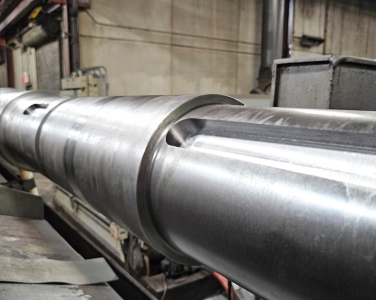

Extrusion Screws and Barrels

The extrusion method works well for creating continuous, long-lasting healthcare products and components. Our parts play an important role in extrusion molding of:

- Medical tubes like drainage tubes, IV tubing, and catheters.

- Graft materials that are utilized in tissue engineering and vascular surgery.

- Guidewires that are produced for use in minimally invasive surgeries.

Blow Molding Screws and Barrels

In manufacturing items for the medical and pharmaceutical industries, blow molding is applied to manufacture hollow products like:

- Containers and bottles to store chemicals, pharmaceuticals, and other medical supplies.

- Blister packs for packing medications and maintaining the sterile nature of medical equipment.

Manufacturing of these packaging items relies on sterile conditions and precision of output. Our feed screws, barrels, and other components play a big role in meeting these standards.

Canadian Feed Screws enhances medical production by supplying premium-quality parts that ensure precision manufacturing and meet the stringiest industry requirements.

Canadian Feed Screws is a company with dedicated employees, decades of experience, innovative machinery, and expansive facility. All these factors enable us to offer optimal engineering and manufacturing solutions, ensuring quality control every step of the way. Our devotion to customer needs sets our products above the competition and gives you components that will withstand heavy duty manufacturing processes and extreme production environments.